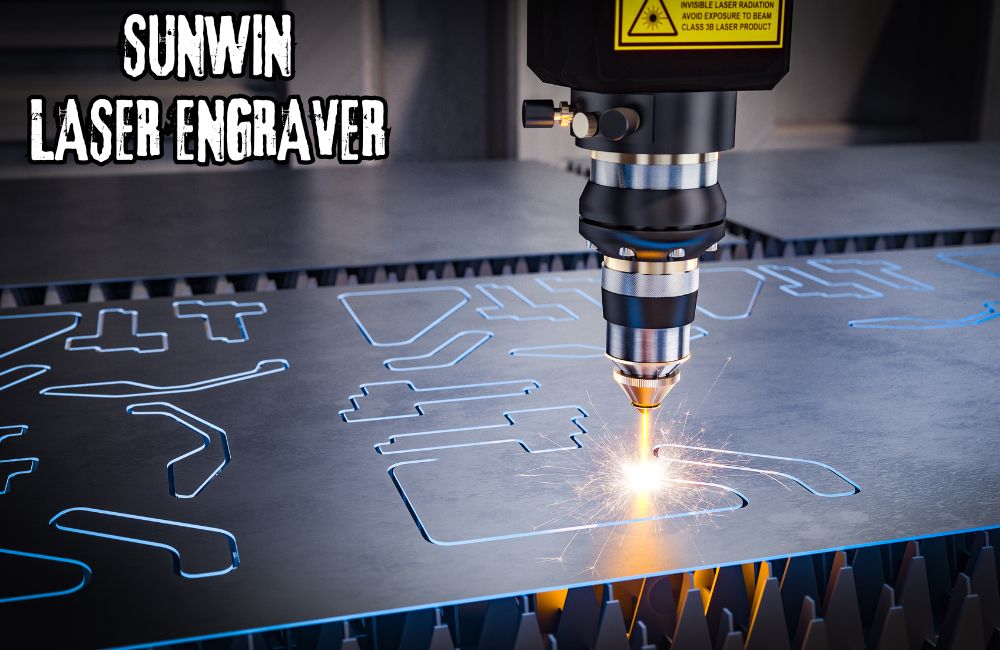

Laser engravers, like the Sunwin model, are becoming increasingly popular for DIYers and professionals alike. However, to get the most out of your Sunwin laser engraver, modifications are often necessary. These upgrades can improve performance, accuracy, and even extend the lifespan of your machine. In this article, we will walk you through how to modify Sunwin laser engraver effectively and safely.

Introduction

The Sunwin laser engraver is a budget-friendly option for those looking to start with laser engraving. While it performs quite well for its price point, it has limitations. Fortunately, with the right modifications, you can significantly enhance its functionality. We will cover the most popular and effective upgrades to optimize your Sunwin laser engraver’s performance.

Why Modify Your Sunwin Laser Engraver?

The default configuration of the Sunwin laser engraver is great for beginners, but it lacks certain features that more advanced users may need. Here’s why you might want to modify it:

- Increased Precision: By upgrading the laser or software, you can achieve more accurate engraving.

- Better Performance: Modifications can enhance speed and power, allowing for faster and deeper engraving.

- Extended Lifespan: Upgrading the cooling system or power supply can prevent overheating and prolong the machine’s life.

These improvements can help you achieve professional-level results without needing to invest in a more expensive machine.

Tools You’ll Need for Modifications

Before diving into how to modify Sunwin laser engraver, gather the following tools:

| Tool Name | Purpose |

|---|---|

| Screwdrivers | For opening and modifying internal components. |

| Multimeter | To check electrical connections and voltage. |

| Soldering Kit | For reworking electrical components if necessary. |

| Laser Safety Goggles | Protect your eyes during testing. |

| Cooling Fans | To upgrade the cooling system and prevent overheating. |

| Upgraded Laser Module | For enhanced precision and power. |

Having these tools ready will ensure a smooth and safe modification process.

Modifications to Improve Performance

1. Upgrade the Laser Module

One of the most effective ways to modify your Sunwin laser engraver is by upgrading the laser module. The stock laser is usually underpowered for certain materials. A more powerful laser, such as a 5W or 10W diode laser, will allow you to cut and engrave thicker materials.

Steps:

- Disconnect the engraver from power.

- Remove the existing laser module by unscrewing the mounting bracket.

- Install the upgraded laser module in place.

- Reconnect the new module to the power supply and control board.

2. Install Additional Cooling Fans

The Sunwin laser engraver can overheat during long engraving sessions, leading to reduced performance and potential damage. Installing extra cooling fans is a simple yet effective upgrade.

Steps:

- Purchase small cooling fans compatible with the engraver’s power supply.

- Mount the fans near the laser module and the power supply unit.

- Wire the fans to the power supply, ensuring proper voltage levels.

3. Upgrade the Power Supply

A weak or inconsistent power supply can result in poor engraving quality and machine instability. Upgrading the power supply can stabilize the machine’s performance and increase the laser’s efficiency.

Steps:

- Identify the current power supply’s voltage and amperage ratings.

- Purchase a power supply with higher wattage and consistent output.

- Replace the old power supply, ensuring all connections are secure.

4. Use Advanced Software

Out-of-the-box, the Sunwin laser engraver often comes with basic software. Upgrading to more advanced laser control software (like LightBurn or LaserGRBL) can provide better control over engraving parameters, such as speed, power, and accuracy.

Steps:

- Download and install the new software on your computer.

- Connect the engraver to the software and configure the settings.

- Test the new software with a small engraving job to ensure everything works.

5. Add a Z-Axis Lifting Platform

The Sunwin engraver lacks a Z-axis adjustment, which limits the range of materials you can work with. Adding a Z-axis lifting platform allows you to adjust the focus and engrave on a wider range of surfaces.

Steps:

- Purchase a compatible Z-axis lifting platform.

- Install the platform beneath the laser module.

- Calibrate the Z-axis to ensure proper focus on various material thicknesses.

Safety Considerations

Modifying a laser engraver involves working with electrical components and high-intensity lasers, so safety is crucial. Always wear protective goggles when testing the laser, and ensure the machine is unplugged when working on internal components. Follow all manufacturer guidelines when handling electrical parts.

Testing After Modifications

After completing the modifications, it’s important to test the machine thoroughly:

- Run a Power Test: Use a piece of scrap material to test the laser’s power output. Adjust settings in your new software for optimal results.

- Check for Overheating: Run the machine for 30 minutes and monitor the temperature to ensure the cooling fans work effectively.

- Evaluate Precision: Use a detailed design to test the accuracy of the upgraded laser module and software.

Can You Make the Sunwin Laser Engraver Bigger?

Yes, you can increase the working area of a Sunwin laser engraver, but it requires careful modification. By expanding the frame and upgrading the mechanical components, you can enlarge the machine’s engraving capacity. However, such modifications demand a good understanding of mechanics, electronics, and laser engraving systems.

Steps to Make Your Sunwin Laser Engraver Bigger

- Expand the Frame:

- The first step is to physically enlarge the frame. You can either build a custom frame using aluminum extrusion bars or extend the current frame by adding additional pieces.

- Ensure the new frame remains sturdy and level to prevent misalignment during engraving.

- Upgrade the Rails and Belts:

- The stock rails and belts may not support a larger frame. Replace them with longer, high-quality rails and belts to accommodate the larger build. Look for precision rails to maintain accuracy.

- Ensure the belts are tensioned correctly to avoid skipping or uneven movement.

- Adjust the Stepper Motors:

- Stepper motors drive the movement of the laser head. With a larger frame, the motors may need to be upgraded for more torque to handle the increased distance and weight.

- You may also need to recalibrate the motor settings in the control software to adjust for the new working area.

- Install a Larger Work Bed:

- The work bed is where you place your materials for engraving. You will need to install a larger bed to match the new dimensions of the machine.

- Ensure the bed is level and compatible with the laser’s focal range.

- Update the Firmware and Software:

- After physically expanding the machine, you’ll need to update the firmware to recognize the new dimensions. Most laser engravers use firmware like GRBL, which can be customized to support larger work areas.

- Similarly, adjust the settings in your laser control software (such as LightBurn or LaserGRBL) to reflect the new dimensions of your engraving area.

Conclusion

Modifying your Sunwin laser engraver can greatly improve its performance, precision, and longevity. From upgrading the laser module to installing advanced control software, these changes can transform your budget-friendly machine into a robust tool capable of professional results. With the right tools and careful execution, you can easily take your laser engraving projects to the next level.

For more in-depth guidance on laser engraver upgrades, you can refer to professional resources for detailed insights.

FAQs

1. Can I upgrade the laser module on my Sunwin laser engraver?

Yes, upgrading the laser module is one of the most effective ways to improve its power and precision.

2. What software works best with the modified Sunwin laser engraver?

Advanced software like LightBurn or LaserGRBL allows for better control and precision over your engraver.

3. How do I prevent my Sunwin laser engraver from overheating?

Install additional cooling fans to regulate the temperature and prevent overheating during long engraving sessions.

4. Is upgrading the power supply necessary for high-performance engraving?

Yes, a more stable and powerful power supply will ensure consistent performance and improve engraving quality.

5. What materials can I engrave after modifying my Sunwin engraver?

With upgrades, you can engrave wood, acrylic, leather, and even some metals, depending on the laser’s power.